In the world of industry, where precision, efficiency, and reliability reign supreme, there exists a silent hero – the electric wire connector. These unassuming components may go unnoticed, but they play a pivotal role in powering, connecting, and optimizing the machinery and processes that drive our modern world. From the sprawling assembly lines of automotive factories to the intricate networks of avionics systems in the aerospace sector, electric wire connectors are the unsung champions that ensure seamless electrical connections. Join us on a journey as we unveil the diverse tapestry of industrial applications where these connectors shine, illuminating the pathways to progress and innovation across a multitude of sectors. Welcome to a world where every connection counts, and where electric wire connectors truly become the lifelines of industry.

Over the past several years, electric wire connectors have become increasingly essential in a wide variety of industrial and commercial applications. In automotive factories, they are used to connect components like sensors, control systems, and wiring harnesses – allowing for precise and reliable operation. In air traffic control systems, they provide power connections between avionics equipment that must be able to withstand extreme environmental conditions. And in manufacturing plants, they are used to join together power-hungry machines – ensuring that operations run reliably and efficiently.

Electric wire connectors play a crucial role in various industrial applications, ensuring the reliable transmission of electrical signals and power.

Here are some other common industrial applications for electric wire connectors:

Automotive Manufacturing: Electric wire connectors are used extensively in automotive assembly lines to connect various components, including sensors, lights, and control modules. They ensure secure connections and facilitate rapid assembly.

Aerospace and Aviation: Aerospace industries use connectors for avionics systems, communications equipment, navigation systems, and more. These connectors are designed to withstand extreme conditions, including high temperatures and vibrations.

Electronics Manufacturing: The electronics industry relies on connectors to link different circuit boards and components within electronic devices, such as computers, smartphones, and consumer electronics.

Industrial Machinery: Manufacturing and processing equipment often use connectors to link sensors, motors, and control panels. They enable the efficient operation of machines in factories.

Energy and Power Generation: Connectors are vital in power generation facilities, including solar farms, wind turbines, and conventional power plants. They help interconnect electrical components, transformers, and power distribution systems.

Oil and Gas: Connectors are used in the oil and gas industry for drilling equipment, pipelines, and offshore platforms. They must withstand harsh environments, including exposure to saltwater and extreme temperatures.

Medical Devices: The medical industry employs connectors in various medical devices, such as diagnostic equipment, patient monitoring devices, and surgical tools. These connectors ensure safe and reliable connections.

Telecommunications: Telecom networks use connectors in data centers, cell towers, and other infrastructure components to maintain high-speed data transmission and reliable communication.

Rail and Transportation: Connectors are essential in the rail and transportation sector for signaling systems, lighting, and control systems in trains, trams, and buses.

Renewable Energy: Connectors are critical in renewable energy projects, such as solar panel arrays and wind turbines, where they connect photovoltaic cells and wind generator components to the electrical grid.

Mining and Construction: Heavy machinery used in mining and construction sites rely on connectors to link power sources to equipment, sensors, and control systems.

Marine and Shipbuilding: Connectors are used in shipbuilding and marine applications for electrical systems, navigation, and communication equipment. They must withstand exposure to saltwater and harsh weather conditions.

Food and Beverage Processing: In food and beverage processing plants, connectors are used to link machinery, sensors, and control systems, ensuring the safe and efficient production of goods.

Chemical and Petrochemical Industries: Connectors are employed in chemical and petrochemical facilities for instrumentation, monitoring, and control of various processes.

Pharmaceutical Manufacturing: Pharmaceutical manufacturers use connectors in their production processes to maintain sterile and controlled environments, connecting sensors and equipment.

The importance of electric wire connectors is only growing. As an increasing number of industries rely on electrical components for their operation, the need for reliable and dependable connections will continue to expand. As a result, significant advances have been made in the design and production of electrical connectors – allowing for greater performance, reliability, durability, and cost-effectiveness.

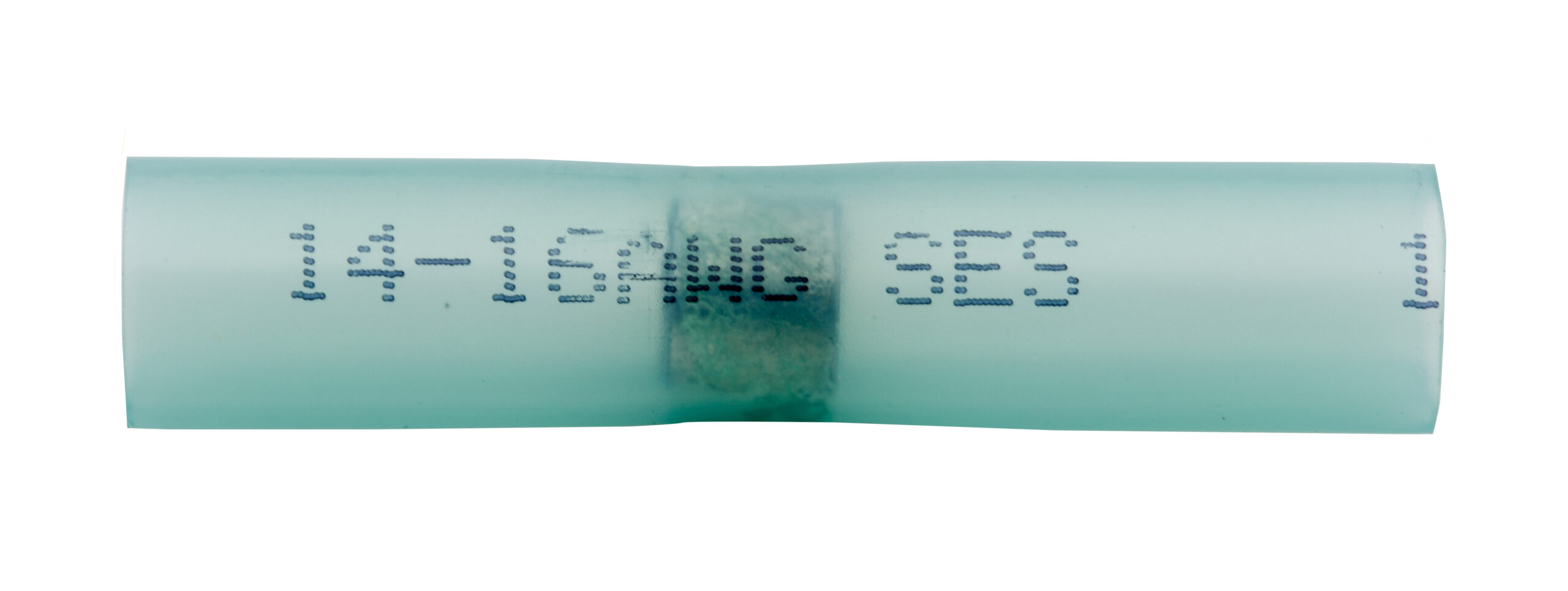

Here at Master Appliance, we offer a wide selection of wire connectors that are built with superior quality and performance to meet the needs of any application. Whether you’re looking for electric connectors for home appliances or aerospace systems – you can find the right solution offered by Master Appliance. Our collection features three brands with different connection types: Proseal, Solderseal & Mulitseal. We offer our wire connectors in assortment kits, mini packs, butt splice connector jars and refill packs.

All of our premium wire connectors are designed with precision and engineered to handle the toughest environments. To shop Master Appliance's premium electric wire connectors click the link here: